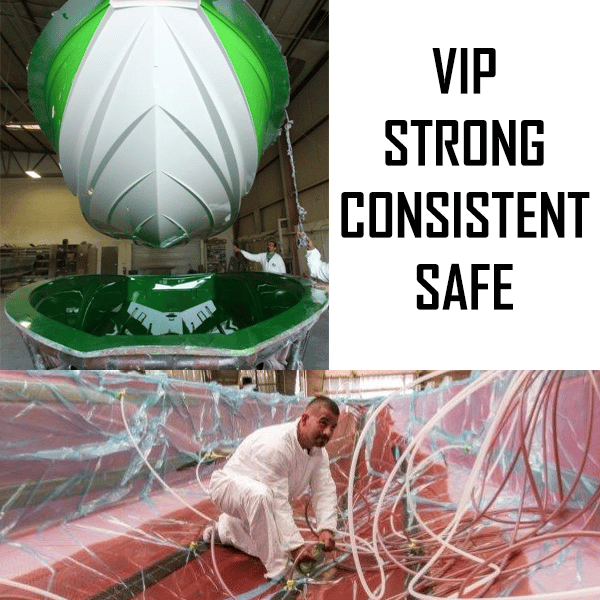

In the continuous quest to produce the world’s best waves, wakes and ride, Centurion Boats has implemented the Vacuum Infusion Processes (VIP) to all towboat model production. The Centurion Leadership Team has implemented the superior craftsmanship of VIP because it creates stronger, more consistent, and environmentally friendly boats.

STRONG & CONSISTENT

A high level of craftsmanship is a cornerstone of Centurion’s mission, and with the Vacuum Infusion Processes, Centurion will continue to produce superior water sports towboats. Each infused part including hulls, floors, RAMFILL tank lids, and tens of small parts receive an exact amount of resin and fiberglass to create a predictable weight. The precise glass to resin ratio under closely monitored vacuum eliminates air voids in the laminate and thereby any weak spots in the structure of the boat. This precise process guarantees strong quality parts, adding another layer of inspired craftsmanship to an already exceptional boat.

SAFE

Take to the water with confidence knowing your boat is built with the environment in mind. VIP is a closed mold process, meaning the resin is cured in a closed environment, and emissions are reduced by as much as 90 percent. Through the Vacuum Infusion Process, Centurion produces less waste, employees can work more comfortably, and less emissions are released into the atmosphere. Everyone wins.

When asked about the return on investment for VIP Paul Singer, President of Centurion & Supreme Boats, responded this way. “While VIP requires higher material costs, slightly longer cycle times and more initial planning, we believe the improved quality and consistency, combined with the environmental benefits, overshadow the additional resources required.” Singer continued, “I am excited about the beneficial impact this new process is already bringing to the boats, our employees and the environment.”

The Vacuum Infusion Process is one of many closed mold processes. It distinguishes itself as the only process to utilize only atmospheric pressure to push the resin into the mold cavity. The process is highly controllable, due to it being governed by the principles of D’Arcy’s Law. This means that there are only three variables affecting the flow of the resin: (1) permeability of the laminate, (2) viscosity of the resin, and (3) pressure differential in the cavity in relation to atmospheric pressure.

VIP supplies a level of strength that is desirable in other industries as well. A major supplier of commercial and defense aerostructures used VIP to develop demonstration wing stiffeners. The eventual goal is to use it to construct entire wing structures. VIP is also used to efficiently manufacture strong rotor blades for wind mills.

Visit your local Centurion Boats Dealer to experience the World’s Best Wakes, Waves and Ride. If you are interested in seeing the Vacuum Infusion Process in action, visit Centurion Boats for a factory tour.